Why OEMs Trust Specialised Automotive Wire Manufacturers?

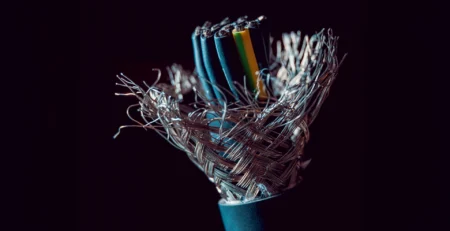

Step into any modern vehicle, and you are stepping into a world connected by wires you will probably never see but can’t do without. These networks carry signals, power, and data, keeping everything from headlights to advanced driver assistance systems running smoothly. Now here is the catch:- as vehicles get smarter, faster, and greener, the wiring behind them grows more complex than ever before.

OEMs face constant pressure—tighter safety standards, rising demand for electric vehicles, and production schedules that never slow down. They can’t afford a weak link. This is where Automotive Wire Manufacturers become the quiet game-changers. They design, test, and deliver wiring solutions that perform flawlessly under heat, vibration, and time constraints. Because for OEMs, trust is not a choice. It is the only way forward.

So, why exactly do manufacturers place such confidence in specialised wiring partners? Let’s break it down.

Why Specialisation Matters in Automotive Wires

Modern vehicles are no longer simple machines. We are discussing sensors, high-speed data systems, electric cars, and safety measures that require accuracy in every wire. By 2031, the Indian automotive wire harness market is expected to have grown from its 2025 valuation of USD 1.91 billion to USD 3.12 billion. With EV sales surpassing 1.5 million units and the rise of ADAS technologies, that represents an 8.48% growth rate.

As production numbers rise—over 26.8 million vehicles in FY 2023–24—the need for automotive cable multicore systems that can handle high voltage, heat, and rapid data transfer keeps growing. OEMs want wiring partners who understand this complexity and deliver cable solutions built for the future.

And that is where specialisation comes in—because making wires for tomorrow’s cars takes more than just copper and plastic. It takes experience, innovation, and a deep understanding of what is at stake.

Quality You Can Rely On: Meeting Stringent OEM Standards

OEMs trust Automotive Wire Manufacturers who don’t just promise quality—they prove it. The best players in the industry work under IATF 16949 and ISO 9001 certifications, ensuring defect rates stay below 0.5%. In contrast, on-time delivery stays above 97%. They use UL, CE, RoHS, and BIS-compliant materials that survive extreme conditions from –40°C to 125°C, even resisting chemicals and flame hazards.

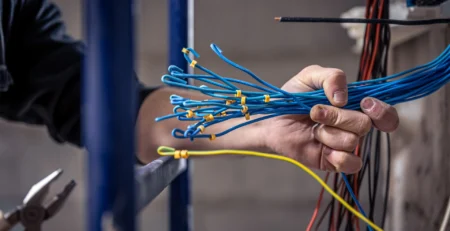

Every automotive cable multicore is tested against ISO 6722 and SAE J1127/J1128 standards. This means when the wiring goes into a vehicle, it is ready to handle real-world challenges without compromise.

For OEMs, this level of quality control removes guesswork. They know each shipment arrives ready for production lines, meeting global safety, performance, and durability benchmarks.

Innovation for Modern Automotive Needs

The rise of electric and hybrid vehicles has changed the game completely. Wiring carries more power, handles more heat, and manages faster data speeds than ever. Leading Automotive Wire Manufacturers are responding with cable solutions that use advanced materials like cross-linked polyolefins and zero-halogen compounds to deliver performance under demanding conditions.

EVs, ADAS sensors, and connected car technologies require modular, lightweight, and heat-resistant automotive cable multicore designs. Indian manufacturers are already adopting precision assembly processes certified under IPC-A-610 Class 2 & 3 standards. This allows them to scale production without losing quality or traceability—something OEMs depend on as vehicle technologies evolve.

Put, innovation in wiring isn’t optional anymore. It is the only way to keep pace with the vehicles of tomorrow.

Supply Chain Confidence: On-Time, Every Time

Even the best cable solutions don’t help if they arrive late. OEM production schedules run like clockwork, so manufacturers need wiring partners who deliver fast and consistently.

That’s why leading Automotive Wire Manufacturers use ERP systems, JIT (Just-in-Time) processes, and EDI-friendly operations. They guarantee short dispatch timelines and maintain centralised manufacturing locations for faster access to every corner of the country and export hubs.

This reliability means fewer headaches, smoother production, and zero surprises when OEMs’ deadlines approach.

Partnerships Built on Communication & Support

A wiring partner’s job does not end after shipping products. OEMs trust manufacturers who offer technical support, dedicated account managers, and responsive communication when questions arise.

With growing complexity in automotive cable multicore systems, this partnership approach keeps production teams confident that help is always a phone call away. It is about building relationships that last beyond one delivery cycle.

And that sense of trust keeps OEMs coming back, project after project.

Sustainability & Responsibility in Manufacturing

The automotive industry is heading toward a greener future, and wiring manufacturers are no exception. India aims to cut manufacturing emissions by up to 87% by 2050 through renewable energy, low-carbon materials, and cleaner supply chains.

Large OEMs are complying with government regulations such as BS6 standards, FAME II incentives, and CAFE2 criteria, as well as pollution reduction goals and EV adoption strategies. Prominent automotive wire manufacturers are adopting environmentally friendly production methods, such as waste reduction programs and solar-powered facilities.

For OEMs, sourcing from sustainable partners supports their green commitments while keeping environmental concerns in check.

How Specialised Wiring Makes OEMs’ Work Easier

At the end of the day, OEMs want simple things:- reliable quality, on-time deliveries, innovative cable solutions, and partners who understand their challenges. Specialised Automotive Wire Manufacturers make this possible with expertise, technology, and a customer-first approach.

When wiring partners get it right, OEMs can focus on building better vehicles instead of worrying about what’s happening under the hood—or behind the dashboard.

Suppose you want automotive cable multicore systems and cable solutions built for speed, safety, and innovation. In that case, it might be time to explore specialised Automotive Wire Manufacturers who understand your production line needs.

After all, great vehicles start with the right connections—literally.