Top Trends in Automotive Wiring Harness Supplies for 2025

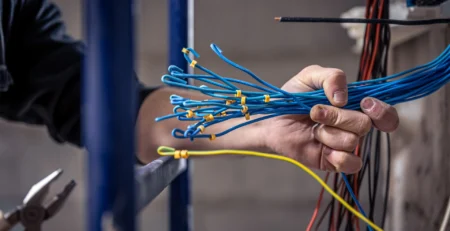

In today’s fast-paced automotive world, wiring harnesses have quietly become the backbone of every vehicle on the road.

Think of them as the nervous system, carrying signals and power to make everything—from headlights to airbags—work just right. But here is the catch: as vehicles get smarter, faster, and greener, the demand for better, tougher, and more efficient wiring is shooting through the roof. Those who supply these critical components can’t just rest on old designs or familiar materials anymore. The game is changing, and staying ahead means embracing fresh ideas, new tech, and smarter ways to deliver.

Automotive wiring harness suppliers are not only pushing wires, but crafting solutions that fit the evolving needs of modern cars. With electric vehicles gaining traction, safety standards tightening, and manufacturing processes becoming leaner, the pressure to deliver quality cable solutions that hold up under stress has never been greater. The challenge? Offering cables that handle extreme heat, resist wear and tear, and plug seamlessly into the supply chain without missing a beat.

Let us unpack the top trends shaping this crucial industry in 2025—and see how these innovations promise smoother rides, safer journeys, and smarter factories.

Lightweight and High-Performance Materials Take Center Stage

Weight matters in automotive design—not just for fuel efficiency but for performance and safety, too.

Wiring harnesses that weigh less but don’t skimp on strength are in huge demand. That means automotive wiring harness suppliers are diving deep into better materials. Copper has long been the standard, but now specially engineered copper alloys that flex and bend without breaking are making waves. These materials can handle more bends—sometimes six times as many—as traditional copper, meaning fewer breaks and longer life.

On top of that, aluminium and tin-plated copper offer lighter alternatives without compromising conductivity. Insulation materials are evolving as well, from classic PVC to high-tech compounds like zero halogen and cross-linked polyolefins, which provide better heat resistance and safety.

These advancements aren’t just about better cables—they’re about cables that fit perfectly with the demands of modern vehicle design, keeping performance sharp and reliability rock-solid. This trend is crucial; as cars get lighter and more complex, wiring can’t be left behind.

Toughness Under Pressure: High-Temperature and Abrasion Resistance

The engine bay is no walk in the park for wiring. Heat, fluids, vibrations, and constant movement can all take a toll. That is why cables need to be ready for battle.

Automotive wiring harness suppliers are now focusing heavily on wires that don’t flinch under extreme temperatures or rough conditions. Special insulation that resists heat and abrasion ensures that wires stay intact even when things get hot and heavy.

Materials like irradiation cross-linked compounds and high molecular density polyolefins offer a protective shield against wear and tear. These cables also handle exposure to oils, battery acids, and other chemicals that are part of daily automotive life. The goal? Cables that not only survive but thrive in the harshest environments.

This kind of durability means fewer breakdowns, safer vehicles, and longer service life—exactly what car makers and consumers want. But these tough materials have to balance flexibility and weight, a challenge the best automotive wiring harness suppliers tackle head-on.

Riding the Electric Wave: EV-Specific Cable Solutions

Electric vehicles (EVs) are no longer the future—they are very much the present. This shift brings a new set of wiring challenges. High-voltage cables, precise sensor connections, and battery management systems need wiring that can handle the electric load safely and efficiently. Automotive wiring harness suppliers working with EV manufacturers must create cables that meet these rigorous demands without adding bulk or weight.

The cables must manage higher currents and temperatures, ensure safety from electrical faults, and integrate smoothly with complex electronics. This calls for a blend of advanced conductor materials and wise insulation choices. Plus, with many EV startups and legacy automakers jumping into the race, the pressure to provide innovative cable solutions fast is intense. Supplying EV wiring is not just about meeting specs—it is about being a trusted partner in the vehicle’s entire design journey, from the initial sketch to the final assembly line.

Safety First: Advanced Insulation for Compliance and Peace of Mind

Cars today are packed with tech, and safety regulations are tighter than ever. Wiring harnesses must meet strict standards for fire resistance, smoke emission, and environmental impact.

This is where advanced insulation materials come in. Zero-halogen compounds reduce toxic gas emissions during fires, while flame-retardant materials prevent the spread of flames. These features protect passengers and first responders alike.

Automotive wiring harness suppliers have expanded their material libraries, including cross-linked polyolefins and ultra-high molecular weight polyethylene (UHMWPE), which combine safety with durability. Offering wiring harnesses that tick all the regulatory boxes is no longer optional—it is essential.

And the best suppliers ensure that meeting these standards does not mean sacrificing flexibility or performance. It is a delicate balance, and those who get it right help make vehicles safer and manufacturers’ lives easier.

Streamlining Supply: Just-In-Time and Smarter Delivery Systems

Even the best cable solutions won’t help if they don’t arrive when and where they are needed. Production lines have strict timetables, and delays can cause everything to go awry. As a result, Just-In-Time (JIT) delivery models are helping automotive wiring harness suppliers adopt smarter supply chains. These methods maintain production lines operating efficiently while lowering inventory expenses.

Modern ERP systems and Electronic Data Interchange (EDI) technology enable real-time tracking of orders from purchase to dispatch. This transparency keeps everyone in the loop, cuts down on errors, and speeds up delivery. For car makers, this means less hassle and more confidence that wiring harnesses will be there exactly when required.

This trend highlights that cable solutions today are not just about the product—they are about the whole process working seamlessly together.

Customized Designs and Value in Every Meter

No two vehicles are exactly alike, so wiring harnesses can’t be one-size-fits-all. There is a growing call for cables designed to match specific vehicle layouts and functions, squeezing out every bit of efficiency and performance. Automotive wiring harness suppliers are increasingly offering consultative support and design collaboration to craft wiring solutions that fit unique needs.

These partnerships focus on value—finding ways to reduce costs without cutting corners, improving ease of installation, or boosting longevity. Workshops and technical sessions with manufacturers help uncover smart design tweaks that save time and money on the factory floor. The move toward more personalized cable solutions makes for better vehicles and happier customers.

Keeping It Green: Sustainability in Cable Manufacturing.

Environmental awareness is not just a buzzword—it is reshaping how wiring harnesses are made and delivered. Sustainable manufacturing practices, including using renewable energy, recycling materials, and minimizing waste, are becoming the norm. Automotive wiring harness suppliers who prioritize green initiatives help the entire industry reduce its carbon footprint.

These actions, which range from solar energy and eco-friendly packaging to rainwater collecting systems at industries, help create a cleaner future. Selecting vendors who genuinely care about sustainability enhances the product and supports larger corporate social responsibility objectives. It is beneficial for better cables and a healthier planet.

Summing Up!

Innovation in the wiring harness industry is booming. Solutions that are more smart, resilient, lightweight, and environmentally friendly than ever before are anticipated by 2025.

Automotive wiring harness suppliers who keep pace with these trends provide more than just cables—they deliver peace of mind, efficiency, and a pathway to success in a rapidly changing automotive landscape. Whether you are working on combustion engines or electric vehicles, under-the-hood heat or delicate sensors, the right cable solutions make all the difference.

By focusing on materials, safety, supply chain agility, customization, and sustainability, suppliers help car makers stay competitive and reliable. The road ahead is exciting, and those who choose their wiring harness partners wisely will enjoy smoother rides, safer vehicles, and stronger businesses.

If you want cable solutions that don’t just keep up but lead the way, it is time to look closely at these trends and the suppliers who live and breathe them every day. The future of automotive wiring is here—and it is wired for success.