Innovations in High-Temperature Automotive Wires for 2025 and Beyond

The drive for innovation in the automobile design industry is still going strong. High-temperature automotive cables are becoming increasingly important as automobiles get smarter, more efficient, and more ecologically friendly. With electric vehicles (EVs) and traditional cars now demanding more advanced systems, the cables that power these systems must be able to handle extreme temperatures without breaking a sweat.

Picture this:- You are designing a car that operates in extreme conditions, from high-performance engines to battery systems in EVs. Electrical current-carrying wires need to be dependable, strong, and efficient even in the face of extremely high temperatures. High-temperature automotive cables are useful in this situation. They ensure that your car runs smoothly, without overheating or compromising safety. With the automotive industry’s growing need for these advanced cable solutions, it is no surprise that high-temperature wires are in the spotlight now more than ever.

Let us explore why these wires are so essential and how they are evolving to meet the needs of tomorrow’s vehicles.

What Makes High-Temperature Automotive Wires Essential?

What do we mean when we discuss high-temperature automotive wires? These cables are made to work in conditions when ordinary cables would not be able to. These wires are designed to withstand extreme heat, whether it comes from an engine or the high temperatures found inside an electric vehicle’s battery compartment.

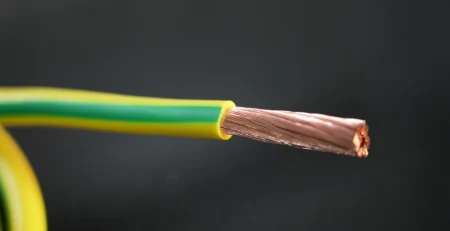

High-temperature wires are typically made with materials like cross-linked polyolefins or zero-halogen compounds, designed to provide thermal resistance and ensure vehicle systems’ safety. The wires are exposed to significant wear and tear in an automotive setting—from engine heat and battery acid to vibrations and friction. That is why choosing the right cable solutions is paramount. The quality and durability of these wires can directly affect vehicle performance and safety.

As vehicles evolve, so too must the wires that power them. High-temperature wires are now seen as a necessity, not a luxury. Without them, the complex systems that keep modern cars running could fail under pressure.

The Growing Demand for High-Temperature Wires in 2025

Due to rising demand from both the traditional automotive production industry and the electric vehicle (EV) market, the market for high-temperature automotive wires is expanding rapidly. This market was estimated to be worth USD 1.2 billion in 2024, and analysts project that by 2033, it will have nearly doubled to USD 2.5 billion. That is a yearly growth rate of about 9%.

The move toward electrification in the automotive sector is also to blame for this increase. The need for cables that can withstand increased heat strains has increased dramatically as EVs gain popularity, particularly in battery systems and power electronics. Actually, the engine under the hood is no longer the only use for these wires. Because the battery and power management systems in electric vehicles run at high temperatures, they are crucial. High-temperature wires are becoming an essential part of vehicle design due to increased safety and performance requirements.

This isn’t just a trend—it’s a reflection of the automotive industry’s commitment to improving both performance and safety. For manufacturers, it’s clear:- if you want to stay competitive, you need to invest in high-temperature cable solutions that meet the demands of the future.

The Role of High-Temperature Wires in Electric Vehicles (EVs)

Electric vehicles are transforming the automotive landscape, and with that transformation comes the need for better high-temperature automotive wires. EVs require sophisticated wiring systems capable of handling fast-charging batteries, thermal management, and advanced power electronics. Wires that can resist heat and maintain performance are more critical than ever.

Consider an EV’s battery systems. During cycles of charging and discharging, these systems produce a lot of heat. The system’s overall safety and effectiveness may be jeopardized if the wires aren’t made to tolerate such temperatures. High-temperature cables can help with it. Even under the most severe circumstances, these wires guarantee that EV systems run effectively and safely.

High-temperature cables not only guarantee dependability but also enhance the overall energy efficiency of the vehicle. Better heat management makes it possible for batteries to operate at their ideal temperatures for longer stretches of time, enhancing the overall performance of the car. As EV adoption continues to rise, these wires will play a key role in supporting the growing demand for more advanced, reliable, and safer vehicles.

Why Innovation in High-Temperature Automotive Wires Matters

Why, then, do manufacturers care about the continuous advancements in high-temperature automotive cables? To put it simply, it’s all about satisfying the needs of contemporary automobiles. Cable wiring systems must adapt to the increasing complexity of cars. The foundation of this advancement is cable systems that can tolerate high temperatures, demanding use, and constantly changing vehicle technology.

With advancements in materials and technology, we are seeing wires that are more heat-resistant, flexible, and durable. For manufacturers, this means fewer breakdowns, less maintenance, and a longer lifespan for wiring systems. As a result, automakers and suppliers who invest in these solutions are not only keeping up with industry trends but ensuring that they can deliver products that meet performance and safety standards.

The evolution of high-temperature wires is directly linked to the broader trends in the automotive sector. As cars become more energy-efficient, as EVs become more mainstream, and as performance demands grow, manufacturers who choose the right wire solutions will be in a position to succeed.

How Balaji Wires Is Shaping the Future of Automotive Wiring

Innovation in high-temperature automotive wires is a game-changer for the industry, and manufacturers must be prepared. Selecting the appropriate cable solutions is important for maintaining the dependability, security, and effectiveness of your car’s wiring systems, not only for the product. Automakers are positioning themselves for success by investing in wires that are strong, long-lasting, and heat-resistant.

Suppose you are looking to stay ahead of the curve. In that case, exploring the high-temperature wire solutions that can support your design needs is essential. Whether you are working on a high-performance internal combustion engine or an electric vehicle battery system, ensuring that your wiring can withstand high temperatures is critical.

Want to learn more about how high-temperature wires can improve your vehicle designs? Reach out to experts in the field and start exploring how the right cable solutions can help your projects succeed.

Summing Up!

The demand for high-temperature automotive cables will only increase due to the growing popularity of electric vehicles and the rising thermal requirements of conventional automobiles. For OEMs and suppliers, these wires are a vital component since they guarantee the efficiency, safety, and performance of contemporary automobiles.

By selecting the best wiring systems for their requirements, manufacturers can stay ahead of the competition and innovate as the market for high-temperature cable solutions grows. You can make sure that your cars are made to last and function at their peak by realizing how important these wires are and making quality material investments.

The car business is changing quickly, therefore it’s time to investigate how high-temperature automotive cables can influence how people travel in the future.