Future Trends: Why EBXL Cables Are the Next Generation of Wiring?

These days, wires not only transport energy. They must be able to withstand pressure, heat, and continuous use without degrading. Conventional wires frequently fail in harsh settings, particularly in solar power plants, electric cars, and contemporary appliances. EBXL Cables takes the lead in this situation. Designed to deliver stronger insulation and higher durability, they are steadily becoming the preferred cable solutions for industries that cannot afford failure.

But what makes them future-ready and different from conventional options?

To understand that, we first need to look at how wiring needs are changing in industries across the world. That brings us to the next part of this journey.

The Shift in Wiring Demand

Cleaner energy, more intelligent machinery, and stricter safety regulations are being adopted by industries. Regular wires are no longer sufficient with this change. They fail when exposed to chemicals and vibrations, melt at high temperatures, or crack over time. Many sectors are now turning to advanced options like Electron Beam Cross-Linked cable technology because they offer more stability and longer service life.

As industries grow more demanding, cables need to match the pace without compromising safety or performance. This change in expectations is exactly what opened the door for EBXL Cables to gain attention.

So what are these cables made of, and why are they different from the rest?

What are EBXL Cables

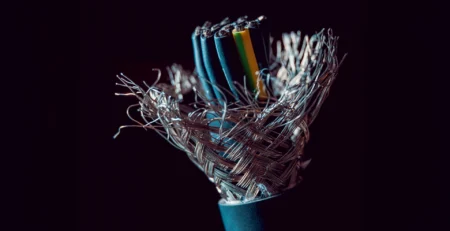

EBXL Cables, short for Electron Beam Cross-Linked cable, are made using a process where high-energy electron beams strengthen the insulation material. This creates a tighter bond within the cable structure, making it more resistant to heat, stress, and ageing. Unlike traditional PVC or XLPE wires, these cables do not soften easily under high temperatures and maintain their performance for a longer time.

They stay flexible, resist cracks, and work efficiently even in tight engine spaces or high-load areas. This makes them highly dependable for industries where performance cannot afford interruptions.

Now that we know what they are, the next step is understanding how they perform compared to traditional wiring systems.

How They Outperform Traditional Cables

Conventional cables start losing strength when exposed to continuous heat, vibration, or moisture. EBXL Cables are built to handle these conditions better. Their insulation stays intact at higher temperatures and does not become brittle over time. This means fewer replacements, fewer breakdowns, and more consistent performance.

They also offer better electrical stability, making them a wise choice for cable solutions used in electric vehicles, solar setups, and automotive wiring harnesses. The risk of short circuits, melting, or insulation failure reduces significantly.

With performance this reliable, it becomes clear why industries are ready to move on from older wiring technologies. The next question is, where are these cables being used the most?

Where EBXL Cables Are Making the Biggest Impact

In industries where regular wires break under duress, EBXL cables are becoming more and more popular. Wiring for electric vehicles must be able to handle voltage fluctuations, battery heat, and small design areas. That’s precisely what these wires accomplish. Solar power systems are resilient to external temperatures, moisture, and sunlight.

They are also preferred in elevators, automated machines, and high-performance household appliances where safety and durability cannot be compromised. Even in automotive wiring harnesses, they handle vibrations, engine heat, and long working hours better than traditional options.

As demand keeps growing, these cables are becoming less of an option and more of a necessity. This shift makes it necessary to ask, are they just better today or built for the future too?

Why EBXL Fits the Future of Wiring

Industries are shifting to more brilliant, safer, and more energy-efficient systems. For wiring to keep up, it must be strong, long-lasting, and safe to use in any condition. That is where Electron Beam Cross-Linked cable technology fits perfectly. It supports higher temperature ratings, longer life cycles, and safer performance.

These features reduce maintenance costs and wiring failures, making it a wise long-term choice. It also meets modern safety standards, which are essential for both domestic and international markets. As businesses focus more on sustainability and performance, reliability is no longer a bonus; it is mandatory.

With this groundwork, it becomes easier to see how manufacturers are adopting EBXL for the next wave of cable solutions.

How Manufacturing is Adapting to EBXL Technology

The rise of EBXL Cables has pushed manufacturers to upgrade their processes. Traditional chemical cross-linking is now being replaced with irradiation technology, which ensures cleaner and more consistent results. Modern facilities are using automated quality checks, advanced insulation materials, and better conductor purity to match international standards.

This shift is not just about meeting demand but about building cables that last longer, perform better, and reduce faults during installation. Many production units now include dedicated testing labs to ensure every Electron Beam Cross-Linked cable meets safety and performance expectations.

With stronger systems in place, the stage is set for these cable solutions to meet global requirements. But where is this technology heading next?

What the Future Holds for EBXL Cable Solutions

Higher temperatures, more compact designs, and more intelligent electrical systems are all part of the future of wiring. Better insulation grades that can tolerate temperatures as high as 150°C will be added to EBXL Cables as they continue to develop. Halogen-free models, which emit less smoke and are hence safer for public buildings and transportation, are gaining popularity.

More industries are expected to switch from PVC and XLPE to Electron Beam Cross-Linked cable technology to meet global quality standards. Export markets are also showing increasing demand for advanced cable solutions that are durable and compliant with safety certifications.

As this shift grows stronger, it becomes essential to summarise why these cables are worth considering right now, not later.

Why EBXL Cables Deserve Attention Today?

Electrical systems are no longer working in controlled environments. They face heat, constant vibrations, moisture, voltage fluctuations, and tighter installations. In such conditions, traditional wiring methods fall short. EBXL Cables offer the reliability needed today by reducing breakdowns, improving safety, and delivering a longer service life.

When compared to standard wires, they offer superior insulating strength, flexibility, and heat resistance. Costly failures in the future can be avoided by selecting the appropriate cable solutions now. Infrastructure, automation, solar, electric vehicles, and other industries have already started the transition to safer and more robust wiring.

So the real question is not whether these cables work well, but whether we are ready to switch to technology that lasts longer and performs better.

Conclusion

The future of wiring is moving towards safer, stronger, and more reliable materials. Electron Beam Cross-Linked cable technology is not a trend; it is a response to what modern systems truly need. EBXL Cables provide better insulation strength, support higher temperatures, and offer dependable cable solutions across industries.

As demand continues to rise, adopting this technology early can help reduce risks and improve performance. If you’re planning new installations or upgrading existing systems, this is the right time to explore EBXL-based wiring.

Want help choosing the right type for your application? Reach out and we’ll guide you through it in a simple, practical way.