How to Choose the Right Silicon Rubber Cable for Your Project

Every industrial setup, big or small, depends on a strong connection that performs under pressure. That connection starts with the right cable in sectors like manufacturing, automotive, or energy. When the environment gets tough, heat rises, or machinery demands consistency, one name stands out — silicon rubber cable.

Durability is not the only consideration when selecting a silicon cable. It involves making sure your systems operate effectively and safely, free from disruptions that cost money and time. It is now essential to have cables that can tolerate high temperatures, fend off corrosion, and maintain their flexibility under trying circumstances. Industries that cannot afford downtime depend on them.

For demanding setups, silicon rubber cable has become a dependable option. Well-known for its great adaptability and heat resistance, it functions well in a variety of settings, including electric cars, building wiring, heavy machinery, and power transmission. It is a dependable component of contemporary infrastructure because of its structure, which guarantees steady electrical performance.

Before we explore choosing the right one, it’s worth understanding what makes these cables different. Knowing what’s inside a silicon cable, what it can handle, and where it performs best can make all the difference between smooth operation and recurring breakdowns.

Every decision in cable selection impacts safety, productivity, and overall cost. That is why it’s crucial to look beyond appearance and price. The correct wire solutions bring a perfect balance of quality, safety, and longevity that supports your project in the long run.

So how do you pick the right one? Let us take a closer look at what makes silicon rubber cables stand apart and how to make the right choice for your needs.

Before deciding what to buy, you must understand what makes these cables unique and why they’re trusted in critical industrial environments.

What Makes Silicone Rubber Cables Special?

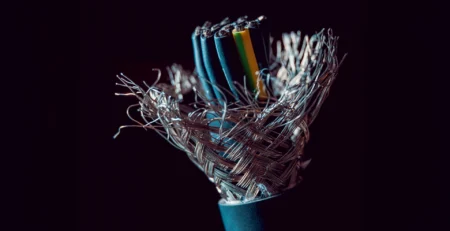

When you hear silicon rubber cable, think of it as a strong yet flexible backbone that keeps power flowing even when conditions get extreme. Unlike PVC or thermoplastic cables that may harden or crack, silicon cable retains its shape and flexibility across a wide temperature range.

The secret lies in its material. Silicone rubber has a cross-linked molecular structure that gives it superior stability. This structure prevents the material from deforming when heat exposure, ensuring consistent insulation and electrical performance. As a result, silicon rubber cable remains reliable in freezing and scorching environments.

Because these cables combine flexibility, insulation, and long life, they are preferred by industries like automotive, electric vehicles, appliances, and aerospace that depend on reliable power transmission. It can withstand temperature changes, the cable is perfect for continuous operation, whether it is installed inside an industrial oven or beneath a car hood.

Silicon UL cables usually meet strict international certification standards, ensuring that their insulation integrity is preserved even in high-voltage systems. When safety cannot be compromised, they are the preferred option due to their chemical stability and flame resistance.

These cables provide excellent dielectric strength and insulation resistance from a performance standpoint. This combination prevents current leakage and maintains efficiency, reducing the risk of electrical failures.

But the appeal isn’t just technical. It’s practical. Wire solutions based on silicone rubber are easy to install and maintain. Their flexibility simplifies routing in confined spaces, saving installation time and effort.

Now that you understand their importance, it’s time to look deeper into what really matters when selecting a silicon rubber cable — starting with its temperature resistance and durability.

Key Factors to Consider Before You Choose

- Temperature Resistance and Durability:-

Any silicon cable’s strength starts with its ability to withstand heat. The remarkable performance of these cables under harsh circumstances is well-known. They can endure temperatures as high as 250°C and run continuously at 180°C without losing their insulation or form. They retain their electrical characteristics and flexibility even at temperatures as low as -90°C.

Their molecular structure ensures they don’t deform or age under thermal stress, making them perfect for industries exposed to fluctuating climates. Because of this, they are widely used in automotive systems, manufacturing plants, and aerospace facilities. Flame resistance and chemical inertness add another layer of safety, reducing the risk of fire or short circuits.

When you think of durability, these cables stand out not only for their performance but also for their longevity. They resist ageing, last longer, and need less maintenance than traditional materials. This reduces downtime and overall operational cost.

Temperature handling is just one piece of the puzzle. The following crucial parameter is how well your cable maintains its electrical integrity under stress.

- Electrical Performance and Safety Standards:-

A reliable cable must have excellent electrical insulation. The dielectric strength of silicon rubber cable typically ranges from 10 to 40 kV/mm, depending on the material. Under BIS and UL standards, these cables are expected to withstand breakdown voltages from 2.5 kV for low-voltage to 36 kV for high-voltage systems.

At 500 V DC, insulation resistance typically surpasses 100 MΩ, guaranteeing little current leakage. These cables are appropriate for demanding environments in India because of their level of safety, which complies with IS 6262 and IS 10810 standards.

Spark safety is equally important. Silicon UL cables used in hazardous areas must prevent sparking during voltage surges. UL 94 and BIS standards categorise materials based on their ability to resist ignition and maintain creepage distance to prevent flashovers.

These parameters make wire solutions built on silicone rubber reliable and safe, even under high load or fluctuating voltages.

Now that we’ve seen the electrical side, let’s focus on how these cables hold up in the face of chemicals, moisture, and environmental wear.

- Chemical and Environmental Resistance:-

Industrial settings are harsh. Oils, acids, UV rays, and ozone can weaken most cables over time, but the silicon rubber cable stands strong. Its resistance to chemical exposure ensures it doesn’t degrade even after prolonged contact with lubricants or solvents.

This makes it ideal for outdoor and chemical-heavy environments like factories and refineries. These qualities also contribute to its long lifespan, meaning fewer replacements and reduced environmental waste.

And while performance matters, flexibility during installation can often decide whether a project stays on schedule.

- Flexibility and Installation Ease:-

Flexibility is one of the most appreciated features of silicon cable. It remains soft and pliable even after long-term use, making it easier to install in tight or curved spaces.

This flexibility means quicker setup and lower labour costs for complex wiring systems.

Combined with lightweight construction, it allows better routing without the risk of cracks or insulation breaks.

Once you have analysed its core characteristics, the next logical step is to match your silicon rubber cable type with the application it best fits.

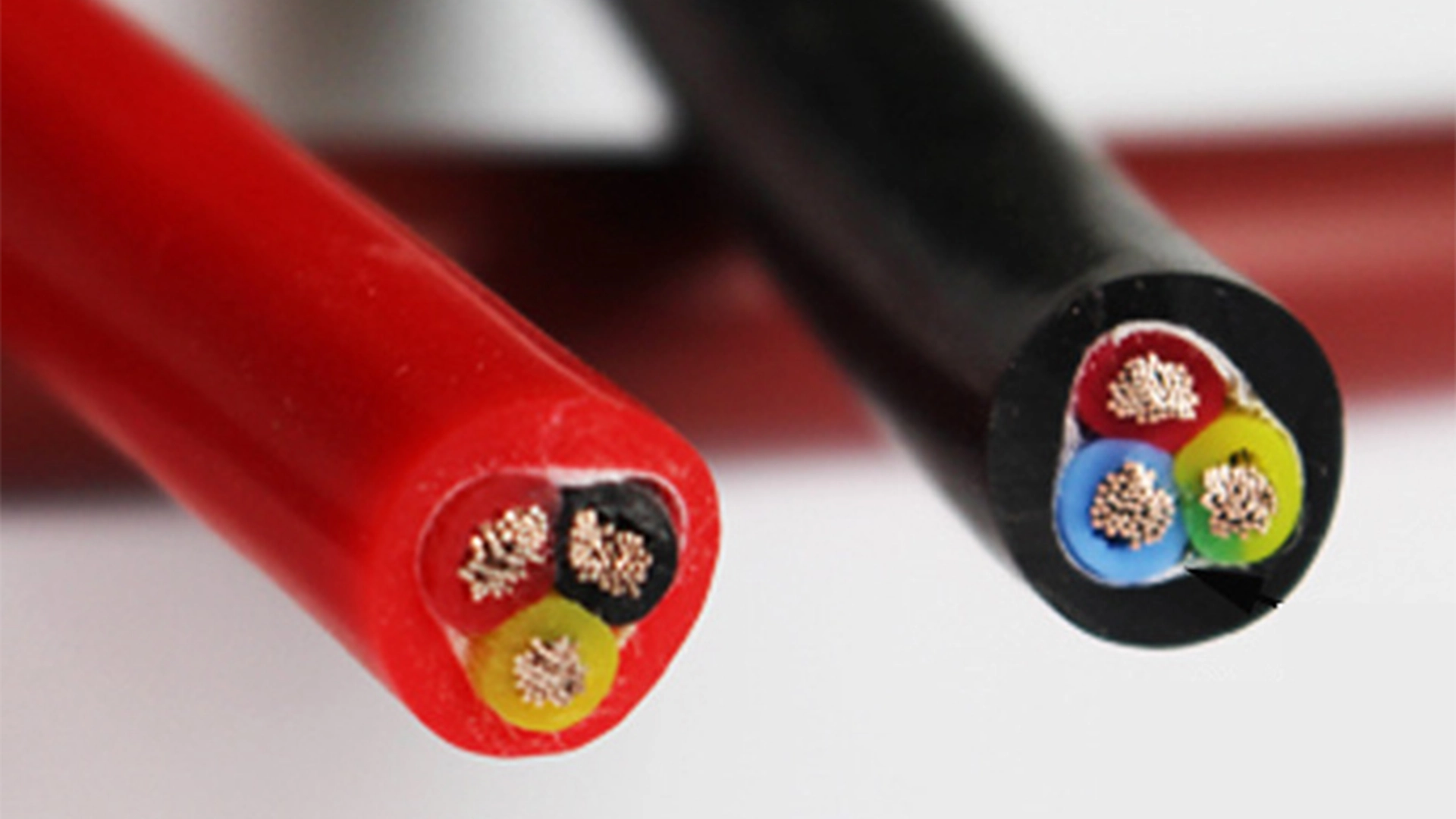

Matching Cable Type to Your Industry Application

Knowing where the silicon rubber cable will be used is the first step in selecting the best one. Cables in the EV and automotive industries are frequently subjected to vibration, heat, and oil. These cables give parts like batteries, headlights, and sensors steady power. Vehicle efficiency and safety are maintained by their resistance to heat.

In industrial machinery, silicon UL cables play a key role in furnaces, sensors, and control systems. Their insulation maintains stability under high voltage, and their flexibility allows easy installation across machines with complex wiring routes.

Appliance and building wiring applications also benefit from these cables. They provide stable performance even under temperature changes or prolonged use, ensuring safety and durability.

You can ensure that your wire solutions offer the best fit for the job by evaluating where and how the cable will be used.

And while application suitability is essential, certifications and compliance guarantee consistent quality and safety.

Certifications and Standards: Your Non-Negotiables

Safety certifications are more than labels. They prove that your silicon cable meets the highest performance and quality requirements. UL and BIS certifications indicate that every cable meter has been tested for temperature, voltage, and spark safety.

The dielectric strength of materials like PVC and polyethene ranges from 10 to 30 kV/mm. UL 1446 and IEC 62114 ensure that cables meet global benchmarks for insulation reliability. For Indian systems, insulation resistance exceeding 100 MΩ at 500 V DC is standard practice.

UL 94 and BIS focus on material flammability and spark resistance. For example, electrical switchgear designed for 11 kV systems must have an insulation level of 28 kV to prevent dielectric breakdown.

Since UL certifies over 22 billion products annually, silicon UL cables certified under this mark signify trusted global quality. Together, these standards keep electrical networks safe, durable, and compliant.

Strong certification is one side of quality. How that quality is built into each cable is what truly defines reliability.

Inside the Process Quality That is Engineered, Not Promised

Every reliable silicon rubber cable is the result of an exacting manufacturing process. High-purity copper conductors, which guarantee superior conductivity, are the first step. Before being shipped, every cable is put through a rigorous testing process to ensure that it is flexible, strong, and insulated.

Advanced machinery and real-time quality checks guarantee uniformity. The use of ERP systems allows complete traceability from raw material to finished product. This ensures that the final wire solutions meet both domestic and international standards.

The manufacturing process also focuses on sustainability. Facilities now integrate solar power, rainwater harvesting, and waste recycling to minimise environmental impact.

Such practices ensure not only performance but also responsibility toward the environment.

However, some common mistakes can undo all the effort, even with the right manufacturing. Avoiding them can save time, cost, and unnecessary failures.

Common Mistakes to Avoid When Selecting Silicone Rubber Cables

The first common mistake is ignoring the temperature range in which your system operates. If the cable’s range is mismatched, it can harden, crack, or lose insulation over time.

The second is overlooking certifications. Not all suppliers provide cables tested under UL or BIS standards. Using uncertified wires can lead to safety risks and non-compliance issues.

Another mistake is compromising on conductor quality. Cheaper options may contain impure copper, leading to resistance and voltage loss. Over time, this reduces efficiency and increases maintenance costs.

Finally, a lot of users disregard installation requirements. If bent past its maximum flexibility, even the best silicon cable may break.

By avoiding these mistakes, you can make sure your wire solutions work as intended.

When reliability and service matter most, working with experienced experts can make all the difference.

Why Partnering with the Right Manufacturer Matters

The right partner does not just deliver cables; they provide trust. With decades of silicon rubber cable manufacturing expertise, the best companies ensure every wire meets strict global standards.

They offer customised support, quick turnaround times, and consistent quality. Having a dedicated technical team means your specific needs — whether for automotive, industrial, or appliance sectors — are fully understood and addressed.

Efficient production and timely delivery also reduce downtime and streamline your supply chain.

When it comes to large projects or export requirements, having a supplier who understands both domestic and global certifications is crucial.

With every factor considered, the final decision comes down to confidence — choosing a product that performs without compromise.

Conclusion – Choose Confidence Choose Reliability

Selecting the right silicon rubber cable involves more than specifications. It is about ensuring safety, consistency, and reliability in every application. These cables keep power flowing without interruption, whether for vehicles, machinery, or industrial systems.

When prioritising durability, flexibility, and certified quality, your investment pays off through long-term performance and reduced maintenance.

The next step is simple. Review your system needs, understand the conditions your cable will face, and match it with the right silicon UL cables that promise endurance and efficiency.

Need expert advice or guidance on choosing the right wire solutions for your setup.

Reach out today, discuss your requirements, and make the choice that keeps your operations running safely and smoothly.