How High Temperature Fluoropolymer Cables Outperform Conventional Insulated Wires

Heat – The Silent Reason Behind Cable Failure

High temperatures inside engines, battery systems, and industrial machines often trigger cable breakdowns long before visible damage appears. Performance declines and downtime rises when insulation degrades or splits.

High Temperature Fluoropolymer Cables can help in this situation. Even when subjected to continuous heat, vibration, or mechanical stress, they are made to provide exceptional thermal stability. Because conventional PVC-based cables can’t always survive harsh environments, industries are moving toward these cutting-edge wire alternatives. Along with heat tolerance, these cables also perform well in areas where chemical resistance is required, making them suitable for spaces exposed to oils, fuels, and battery fumes. Their reliable electrical properties ensure consistent signal flow and power transmission.

This shift has not happened overnight. It results from rising safety requirements, evolving machinery, and a growing need for long-lasting wiring systems. Regular wires face limitations in harsh conditions.

To understand why these cables are becoming the preferred choice, it is important to look at the science behind them.

What Sets Fluoropolymer Cables Apart?

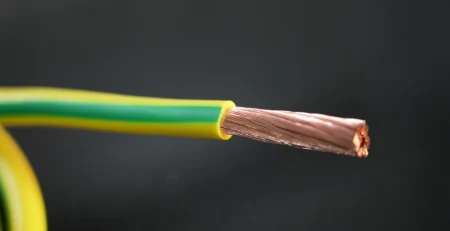

High Temperature Fluoropolymer Cables are designed to withstand continuous exposure to intense heat without melting or cracking, in contrast to traditional PVC or rubber-based insulation. Because of their exceptional thermal stability, they can continue to operate even at temperatures far higher than those that conventional wires can withstand.

In sectors where equipment operates regularly, reliable wire solutions are critical to both efficiency and safety. In addition, these cables have robust electrical characteristics that guarantee appropriate conductivity under a range of loads and voltages. They are more reliable because of their great chemical resistance, which shields them from industrial solvents, coolants, acids, and engine oil.

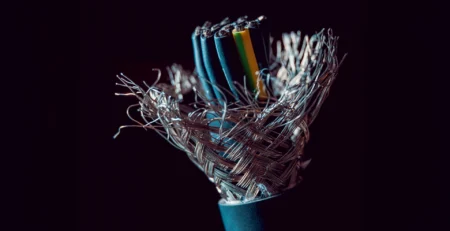

Their unique structure gives them strength without adding unnecessary bulk. This makes them suitable for compact spaces in electric vehicles, control panels, and battery systems.

While their benefits are technical, their real value appears in factories, vehicles, and heavy-duty machines where failure is not an option.

Moving forward, a minute comparison can help highlight how they outperform conventional options.

Fluoropolymer vs Conventional Insulation.

Standard wires can handle routine usage but fall short in high-heat environments. High Temperature Fluoropolymer Cables have superior thermal stability, ensuring performance even when engine bays, furnaces, or battery terminals heat up.

Additionally, they reduce voltage drops and disruptions by maintaining constant electrical qualities. These qualities help prevent frequent replacements for companies that depend on long-term cable solutions.

Chemical resistance is another important distinction. When conventional insulation deteriorates because of oil or acidic vapors, fluoropolymer-based products remain stable.

Conventional materials often harden or crack over time under stress. In contrast, fluoropolymers stay flexible and durable even when exposed to constant vibration. They also resist moisture, sunlight, and mechanical wear.

This difference does not only affect performance. It affects safety, operational costs, and trust in the system.

With these technical strengths in mind, it becomes easier to understand where these cables bring the most benefit.

Where These Cables Make A Real Difference

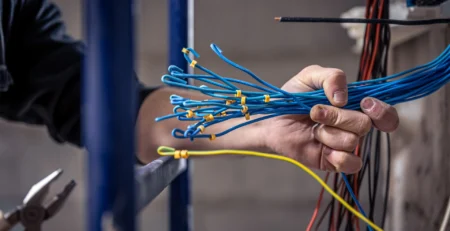

Industries working with extreme heat and continuous load often shift to High Temperature Fluoropolymer Cables because of their superior thermal stability. Their robust electrical characteristics provide dependable current flow in EV battery circuits, industrial heaters, and automobile engines. They are also favored in industries where long-term performance requires dependable wire solutions. They are perfect for factories that frequently deal with grease, fuels, and acids because of their chemical resistance.

In electric vehicles, where wiring moves through tight spaces and high-voltage circuits, longevity matters. In battery manufacturing, constant thermal exposure and corrosion risks make safety critical.

These cables are not just used in high-end technology. Even in basic machinery or control panels, they provide assurance where failure could lead to loss or downtime.

Now that their applications are clear, the next question is what makes their material behave differently.

Why Their Material Composition Matters

A substance intended for exceptional heat stability is at the heart of High Temperature Fluoropolymer Cables. Insulation stays stiff even at high temperatures because fluoropolymers are hard to soften.

Cleaner current transfer is made possible by improved electrical properties, which reduce power loss in delicate systems. These characteristics make them reliable cable solutions in industries where accuracy is crucial.

Fluoropolymers do not readily absorb moisture, in contrast to traditional insulation. Even after extended exposure to sunshine or pressure, they maintain their suppleness without swelling or splitting. As a result, maintenance expenses are reduced and fewer replacements are needed.

With material benefits understood, it is important to see why so many industries invest in them, especially when reliability directly affects production.

Why More Manufacturers Prefer Them

Because High Temperature Fluoropolymer Cables have better thermal stability, manufacturers who utilize them report fewer malfunctions. These cables ensure long-lasting electrical properties that increase trust in equipment that runs continuously. As businesses look for reliable cable solutions, this creates a strong case for adoption. They perform well in environments including gasoline, grease, and industrial pollutants because of their chemical resistance.

Their thin insulation and lightweight structure also allow more wiring in compact spaces without increasing weight, making them ideal for electric vehicles and aerospace applications. Beyond performance, they support compliance with global safety standards.

Understanding what industries value makes it easier to evaluate if your setup needs this upgrade.

How To Know If It Is Time To Switch?

If wires are subjected to continuous heat, vibration, acid vapors, or electrical load, standard insulation might not be sufficient. Unstable connectivity, melting insulation, and frequent cable replacements are early warning indicators. In these circumstances, switching to high-heat cables can lower long-term expenses, increase efficiency, and reduce risk.

Industrial plants, EV manufacturers, furnace operators, and battery assembly units often reach this decision when maintenance becomes frequent or safety becomes a concern.

Better wiring is not only about performance. It is about preventing minor issues from turning into major failures.

Once that decision is clear, the next step is choosing a reliable partner who understands materials, manufacturing, and testing.

Choosing The Right Manufacturing Partner

A good manufacturing partner does not just supply cables. They understand application needs, insulation materials, conductor quality, and compliance standards. Experience in automotive, electrical, and export markets adds assurance. The ability to test, certify, and support design requirements is very important.

Look for a partner who uses high-purity copper, follows strict quality systems, and offers quick delivery timelines. Support in documentation, export compliance, and after-sales guidance can significantly impact project execution.

Selecting the right partner ensures every cable installed today continues working safely for years.

With the proper support, shifting to better wiring becomes a smooth process instead of a complex technical change.

Smarter Wiring For Safer Performance

Heat, corrosion, and electrical stress are part of modern machinery. Cables that can withstand these challenges offer more than performance. They offer safety, uptime, and peace of mind. High-performance wiring is not just a technical upgrade. It is a long-term step toward safety and reliability.

Feel free to start a conversation if you are exploring better options or want guidance on which cable fits your system. We are here to help you make the right decision.